T4

With the T4 adhesive tape printing machine, you can get high quality prints of up to 4 colors at high speed.

Tape

Printed Tape

The T4 Adhesive Tape Printing Machine, developed by Flexoteknik, is a flexographic printing press specifically designed for industrial tape production, offering high quality, speed, and efficiency. This machine is capable of printing on a wide range of adhesive tape types, including hotmelt, solvent, acrylic, and water-activated tapes. Its versatile design adapts to different substrate thicknesses, providing maximum flexibility and functionality for production processes.

With its ability to produce custom printed tape at scale, the T4 model meets the needs of businesses looking to brand their packaging or communicate key messages directly on their adhesive products. The machine can print up to 4 colors, delivering vibrant and crisp visuals. With a printing width of up to 300 mm, it caters to a wide range of applications. Operating at a speed of up to 120 meters per minute, the T4 can produce up to 1800 m² of printed product per hour — making it an ideal solution for companies with high-volume custom printed tape production requirements.

The machine is compatible with solvent-based, water-based, and alcohol-based inks, offering flexibility to meet various printing demands. An electric heater-driven hot air drying system ensures fast and consistent ink drying, preserving print quality throughout production. For enhanced adhesion on plastic-based surfaces, the T4 includes a built-in corona treatment unit, enabling sharp and durable results even on low-energy substrates commonly used in custom printed tape manufacturing.

Designed with Flexoteknik’s proven engineering expertise, the T4 Adhesive Tape Printing Machine is a reliable, innovative, and long-lasting solution for businesses producing custom printed tape. Its material compatibility, consistent print quality, and high-speed performance have made it a preferred machine for manufacturers around the world looking to stand out in the competitive packaging industry.

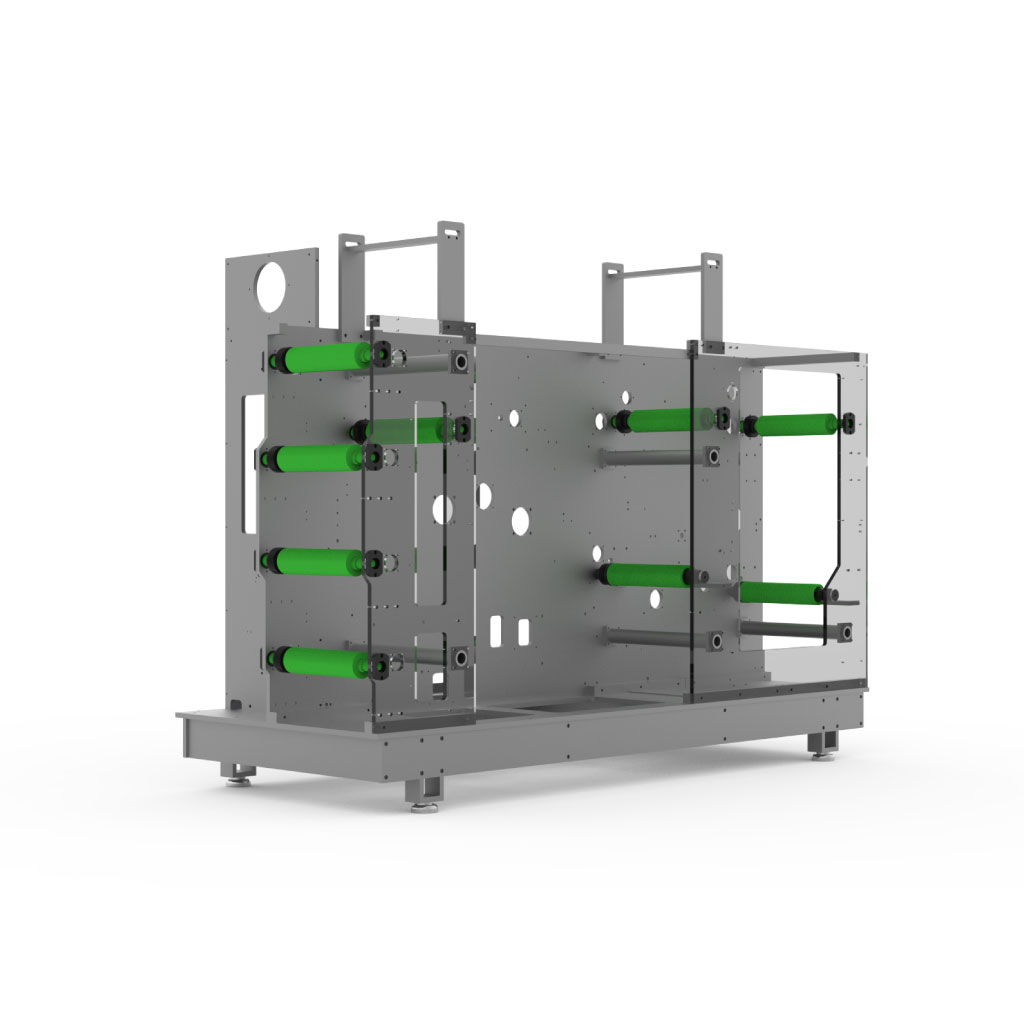

Mutually fixed traction rollers

Thanks to the mutual fixing of the drive rollers, your machine works more efficiently for many years, so you can always obtain quality prints.

Precise prints up to 4 colors

You can get quality and fast prints in up to 4 colors with printing units with customizable Anilox values.

Completely Aluminum Chassis

Produced with high quality, 5000 series aluminum is processed on CNC machines to ensure stable printing even at high speeds.

What types of adhesive tapes can T4 print on?

1. Solvent Tapes

- Contains solvent-based rubber adhesive.

- Offers high adhesion and durability.

- Resistant to both cold and hot temperatures.

- Provides resistance to moisture, chemicals, and UV rays.

2. Acrylic Tapes

- Contains water-based acrylic adhesive.

- Provides medium-level adhesion.

- Resistant to UV rays.

- Has a long shelf life and does not yellow over time.

3. Hotmelt Tapes

- Uses synthetic rubber-based adhesive.

- Provides high initial adhesion.

- Bonds quickly and strongly.

- Offers moderate resistance to moisture and impact.

4. Water-Activated Tapes

- Contains natural starch-based adhesive.

- Activates with water to create a strong bond with the surface.

- Eco-friendly and recyclable.

- Adheres to the entire box surface, making tampering attempts visible.